Key plan in top right-hand corner of the drawing Plant North arrow (up or to the left) in top left-hand corner of drawing Locations of supports, identified by pipe support number. On screwed and socket-welded assemblies, valve handwheel positions need not be shown. Unions required for installation and maintenance purposes. Number, location, and orientation for each instrument connection. Size, pressure rating, and instrument number of control valves. If a flange is different from the specification for the connected pipe, then the details of the flanged nozzles on equipment to which piping has to be connected should be included.

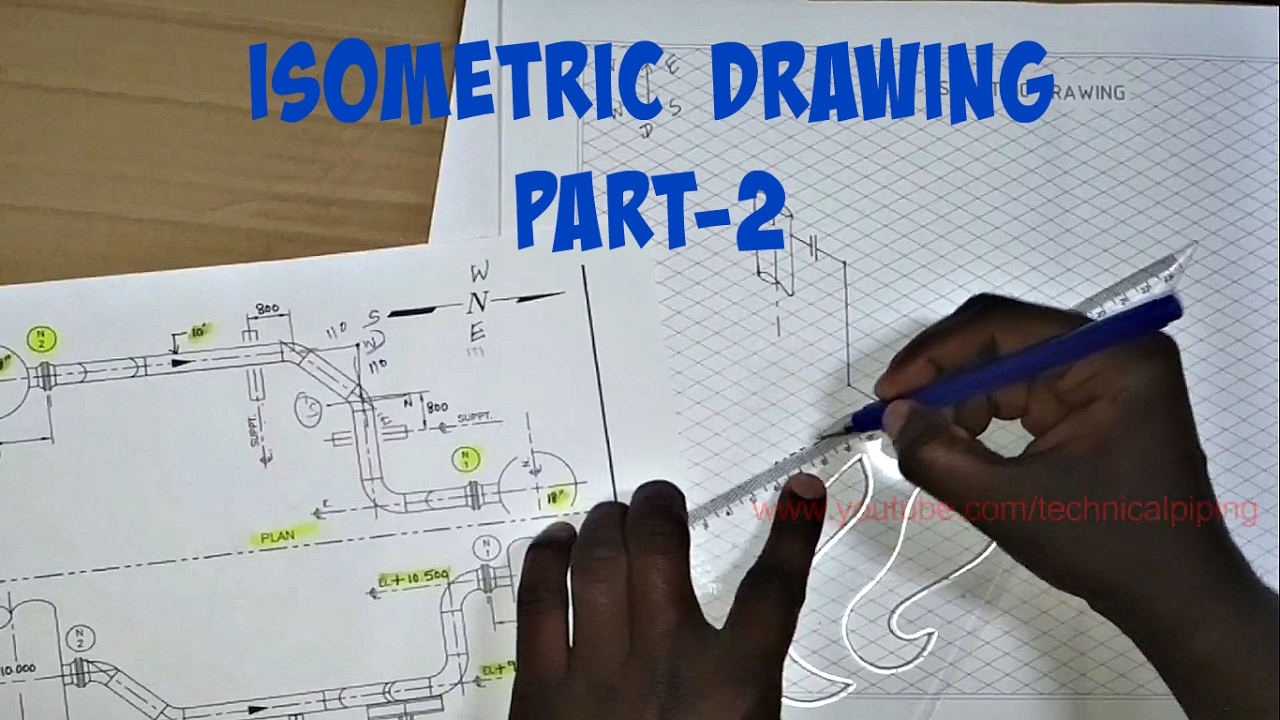

Identify of all items by using common symbols and a description if necessary. Įquipment numbers and locations of equipment.Reference number of plan drawing from which an ISO is made, line number, direction of flow, insulation, and tracing. Items and information that are shown on an ISO include the following: The various runs of pipe, fittings, and valves should be roughly in proportion for easy understanding. It gives all information necessary for fabrication and erection of piping. Piping “isometric” and “spool” drawings shows a complete line from one piece of equipment to another. Figure 13.8 illustrates the representation of the north arrow on the arrangement drawing and the north arrow on the isometric. In the piping discipline a north arrow is used as a “point of reference.” Accurate isometric layout is based on the correlation of the orientation of the north arrow on the Piping Arrangement drawing and the north arrow on the piping isometric. The complexity of piping configurations requires a more descriptive “point of reference” be used to establish orientation between the orthographic and isometric views. Although the A can be seen in Figures 13.3 and 13.4, it is not an adequate point of reference. Similarly, on piping isometrics, establishing a point of reference is imperative. By using a point of reference, proper orientation of the isometric can occur by transferring distance and direction from the orthographic view. Note in Figures 13.1 and 13.2 how the height, width, and depth dimensions of the L-shaped object in the orthographic views are oriented on the isometric view with A as a point of reference.

0 kommentar(er)

0 kommentar(er)